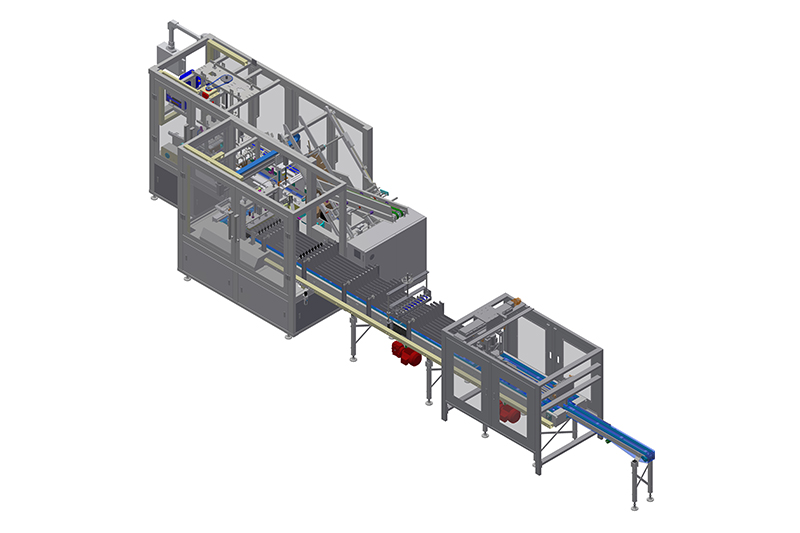

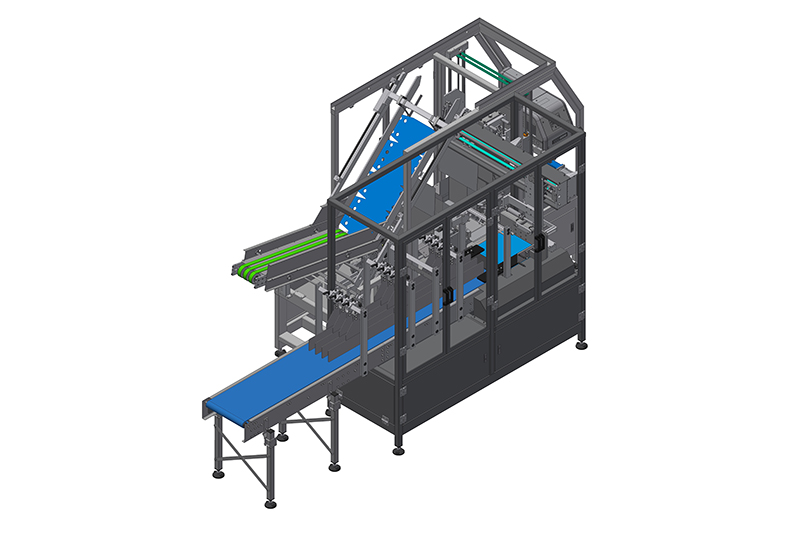

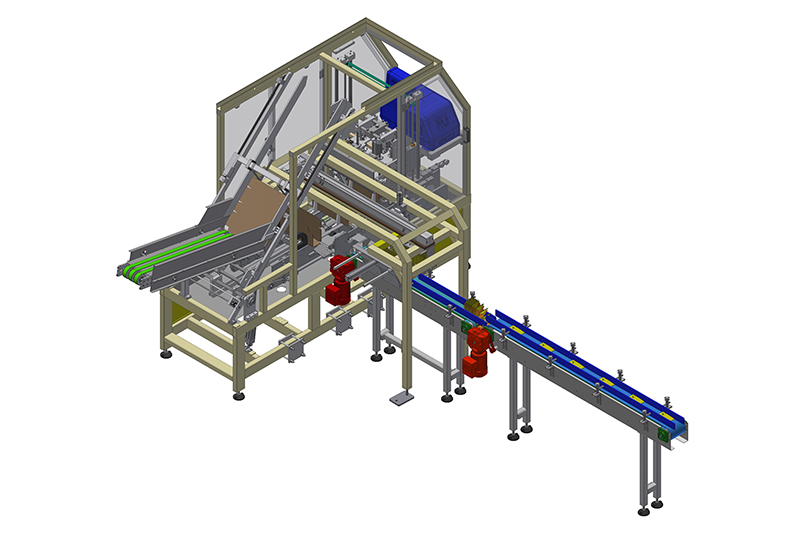

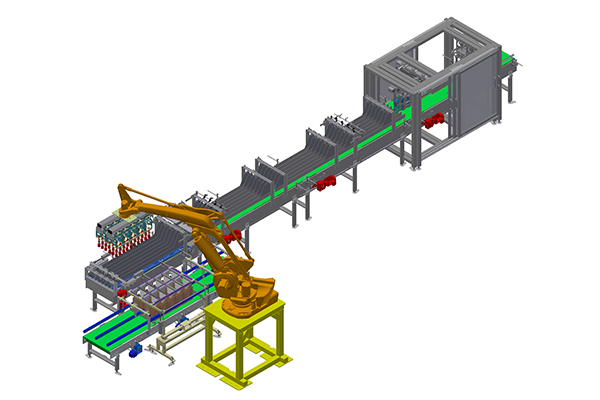

Side loading wraparound case packer

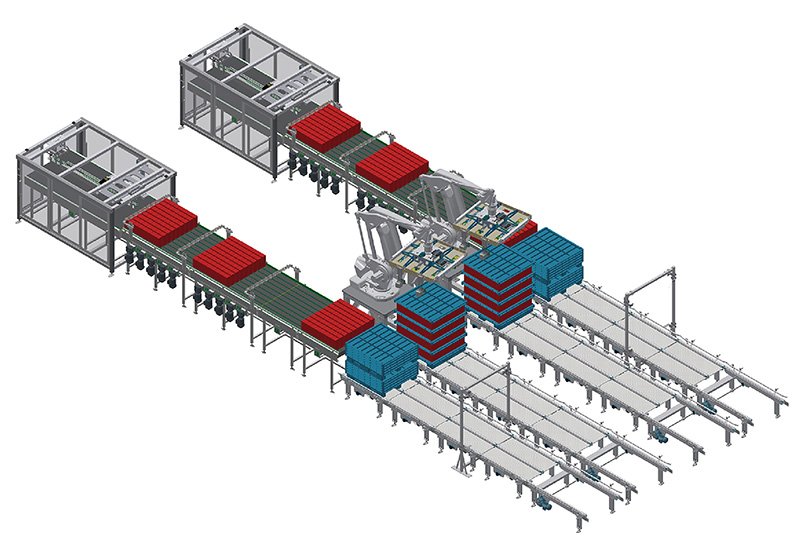

The benefits of wraparound case packing are numerous, such as the cost per blank cardboard is less due to the unglued manufacturer’s joint, and it improves palletizing performance because the loaded Wrap Around cases are more square than a typical RSC type case.

Wraparound case packing machine is widely used in water beverage, dairy and food industries. It can automatically pack bottled and tinned products by wrapping cartons, greatly improving production efficiency and saving packaging costs.

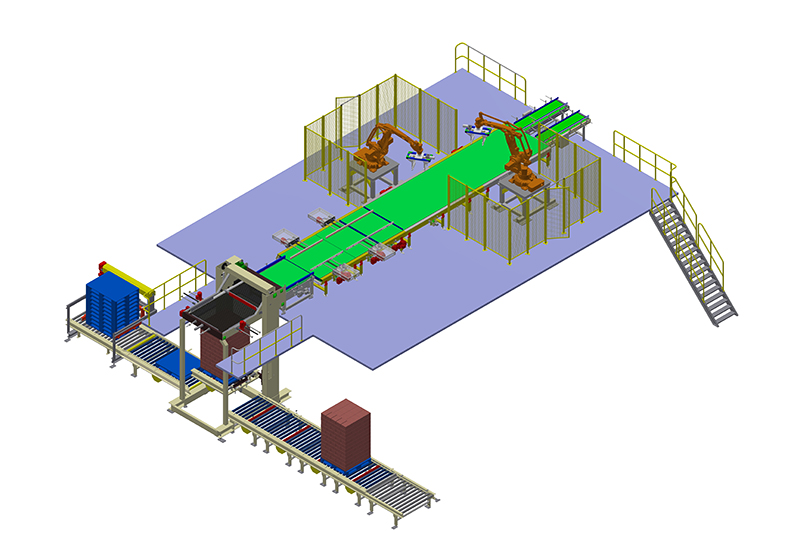

Working flow

During case packing production, the infeed conveyor transports the small packs into machine, and be arranged into 2*2 or 2*3 or other arrangements, and then the servo modular push the packs into the half shaped carton, and the carton will be wrapped and sealed by hot melt glue.

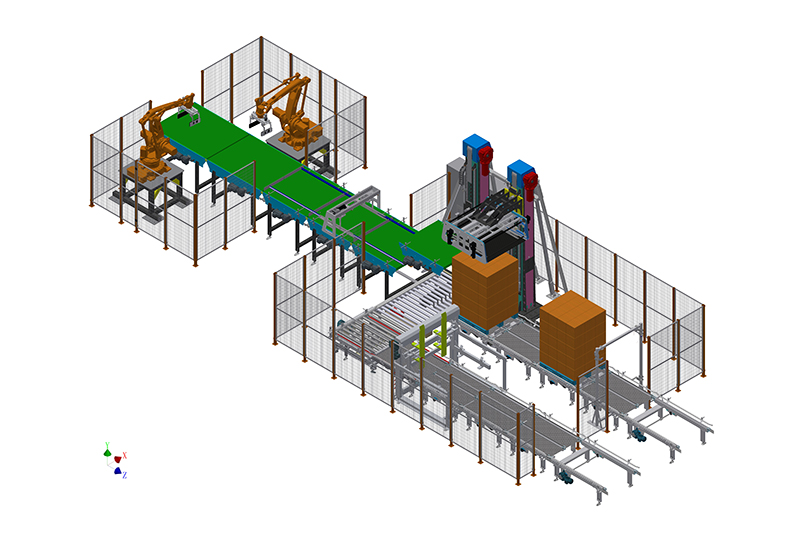

• Greater utilization through precise and repeatable changeovers

• Case forming and sealing systems engineered to produce optimal package quality

• Sanitary construction options to meet environmental and cleaning requirements

• Precise and repeatable machine motions - velocity, speed and position control

• Engineered and proven product handling, collation and loading technology

• More speed, more control, more efficiency, more flexibility

Main configuration

| Item | Specification |

| PLC | Siemens (Germany) |

| Frequency converter | Danfoss (Denmark) |

| Photoelectric sensor | SICK (Germany) |

| Servo motor | Siemens (Germany) |

| Pneumatic components | FESTO (Germany) |

| Low-voltage apparatus | Schneider (FRANCE) |

| Touch screen | Siemens (Germany) |

| Glue machine | Robotech/Nordson |

| Power | 10KW |

| Air consumption | 1000 L/min |

| Air pressure | ≥0.6 MPa |

| Max Speed | 15 carton per min |

Main structure description

- 1. Conveyor system:the product will be divided and inspected on this conveyor.

- 2. Automatic cardboard supplying system: This equipment is installed in the side of the main machine, which stores the carton cardboards, the vacuumed sucking disk will indraft the cardboard into the guide slot, and then the belt will transport the cardboard into the main machine.

- 3. Automatic bottle dropping system: This system separates the bottles in carton unit automatically, and then drops the bottles automatically.

- 4. Cardboard folding mechanism: the servo driver of this mechanism will drive the chain to fold the cardboard step by step.

- 5. Lateral carton pressing mechanism: the lateral cardboard of carton be pressed by this mechanism to form the shape.

- 6. Top carton pressing mechanism: The cylinder presses the up cardboard of the carton after glueing. It is adjustable, so that it can suitable for different size of carton

- 7. Automatic system control cabinet

Case wraparound machine adopt Siemens PLC to control the complete system of the machine.

The interface is Schneider touch screen with good display of production management and status.

More video shows

- Wrap around case packing for aseptic juice pack

- Wrap around case packing for grouped beer bottle

- Wrap around case packing for milk bottle

- Wrap around case packing for filmed bottle pack

- Wrap around case packing for small bottle pack (two layers per case)

- Side infeed type wraparound case paker for tetra pack (milk carton)

- Wraparound case packer for beverage cans

- Tray packer for beverage cans